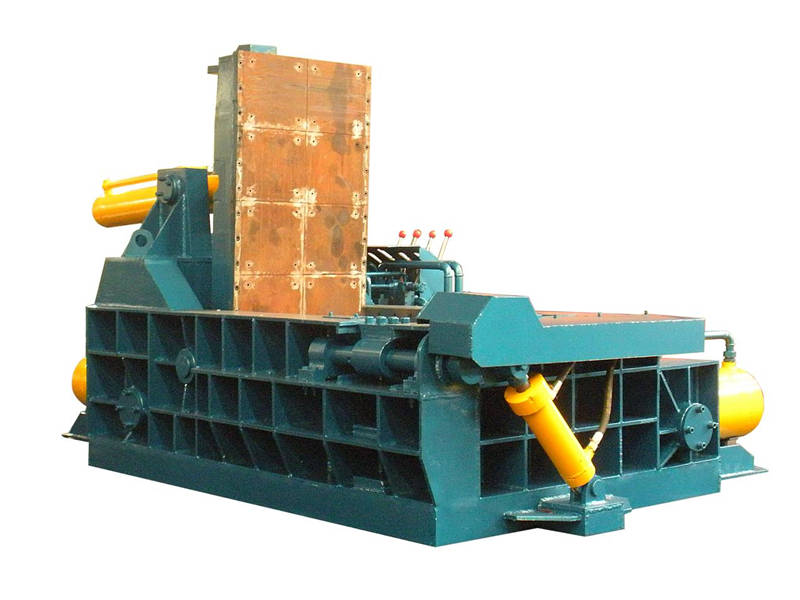

metal scrap baling press machine

Metal scrap baling press machine, also known as a metal baler, is a machine designed to compress different types of metal into a transportable and storage-friendly bale.

Capabilities: A high-quality metal scrap baling press machine is capable of compressing various metals such as iron, steel, aluminum, brass, and much more. The machine is capable of processing single, double, or triple-compression bales. These machines help recycle metal waste and transform it into a valuable resource.

Material: Typically, these machines are made from hard-wearing, high-strength, and durable materials like steel or heavy-duty cast iron. This ensures resistance to wear, corrosion, impact, and high stress, optimizing their lifespan and productivity.

Working principle: The fundamental working principle of a metal scrap baling press involves applying high pressure to metal scrap using hydraulics. The pressure causes the metal to deform and take the shape of the bale chamber. After reaching the desired size and density, the compressed metal is bound using wires and ejected from the bailing chamber.

In professional English terms, the baling press machine is split into a variety of components: the mainframe featuring the pressing room, hydraulics, control systems, bailing chamber, and wire threading device. The optimum functioning of these parts ensures the production of consistent, high-density bales, reducing the volume of materials and aiding in efficient transportation and storage.